Rethink Your Veterinary Sterilization Method

Sterilization is a critical part of any veterinary clinic’s operations. It ensures that surgical instruments and delicate medical tools remain safe and effective for procedures. For years, many clinics have relied on Amprolene (ethylene oxide) sterilizers, but have you ever considered the risks and limitations that come with it?

The Hidden Risks of Amprolene Sterilization

While Amprolene has been a common choice for sterilization, it carries significant disadvantages that many clinics may not be fully aware of:

- Health and Safety Risks

Amprolene, or ethylene oxide, is a known carcinogen. Long-term exposure to its fumes can pose serious health risks to veterinary staff, including respiratory issues, headaches, and even increased cancer risks. Proper ventilation and strict handling protocols are required to minimize exposure, but even with precautions, the risks remain. - Extended Sterilization Time

The sterilization process with Amprolene can take up to 24 hours before instruments are safe to use. This delay can be a major inconvenience, especially in busy clinics where quick turnaround times for surgical tools are essential. - Environmental Concerns

Ethylene oxide is classified as a hazardous air pollutant. Its use requires strict environmental regulations, and improper disposal or leaks can have severe consequences. Many industries are moving away from it in favor of more sustainable and eco-friendly alternatives. - Cost and Compliance Challenges

With increasing regulations surrounding the use of ethylene oxide, clinics face additional compliance costs, specialized storage requirements, and expensive disposal procedures. Over time, these add up, making Amprolene an inefficient and costly solution.

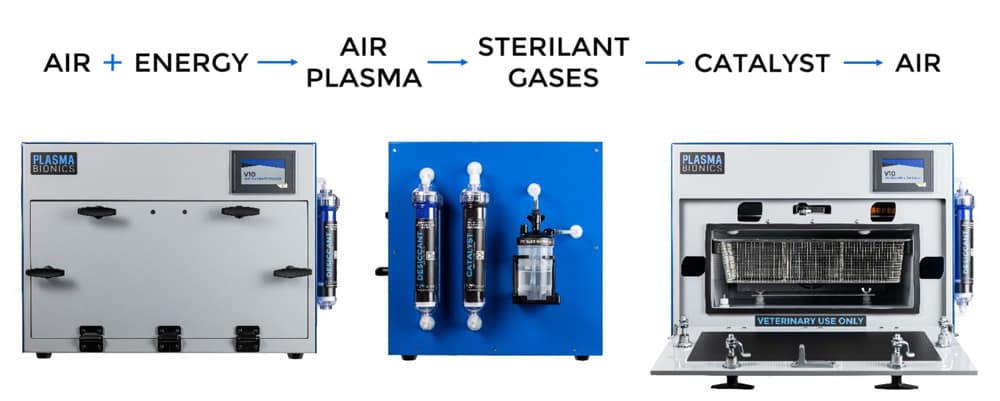

A Safer, Faster, and More Efficient Alternative: The Plasma Bionics V10 Sterilizer

If you’re looking for a safer, more efficient, and eco-friendly way to sterilize your instruments, the Plasma Bionics V10 is the game-changing solution your clinic needs.

Why Choose the Plasma Bionics V10?

Non-Toxic & Safe for Staff

The V10 does not use toxic components for sterilization, eliminating the health risks associated with ethylene oxide. No toxic emissions, no carcinogens, and no need for extensive ventilation systems. In fact, this is one of the key differences of the unit.

The Air Plasma Sterilization® process generates plasma directly from air within the sterilization chamber, making it the sole source of sterilant production. The only inputs required are air and electricity. This process produces multiple ions, charged particles, and reactive oxygen and nitrogen species—such as ozone, nitrogen dioxide, hydroxyl radicals, and nitric oxide—creating a multi-pronged approach to effectively eliminate microorganisms from the surfaces of sensitive veterinary instruments.

Rapid Sterilization in Just 4 Hours

Unlike Amprolene, which can take up to 16 hours, the V10 completes a full sterilization cycle in 4 hours, allowing clinics to use their instruments the same day.

Eco-Friendly & Compliant

The V10 does not produce harmful emissions, making it a much more sustainable choice. It meets modern environmental and safety standards without the regulatory headaches of ethylene oxide.

Gentle on Instruments

Designed for heat- and moisture-sensitive instruments, the V10 ensures your equipment stays in top condition, prolonging its lifespan and reducing replacement costs.

Is It Time to Upgrade Your Sterilization Process?

Many veterinary clinics stick with Amprolene simply because it’s what they’ve always used. But with mounting safety concerns, long sterilization times, and increasing regulations, it’s worth asking: Is it still the best option for your clinic?

The Plasma Bionics V10 offers a modern, safe, and efficient alternative that eliminates the risks of ethylene oxide while improving your workflow.

Ready to make the switch? Contact Dispomed today to learn more about the Plasma Bionics V10 and how it can transform sterilization in your clinic.