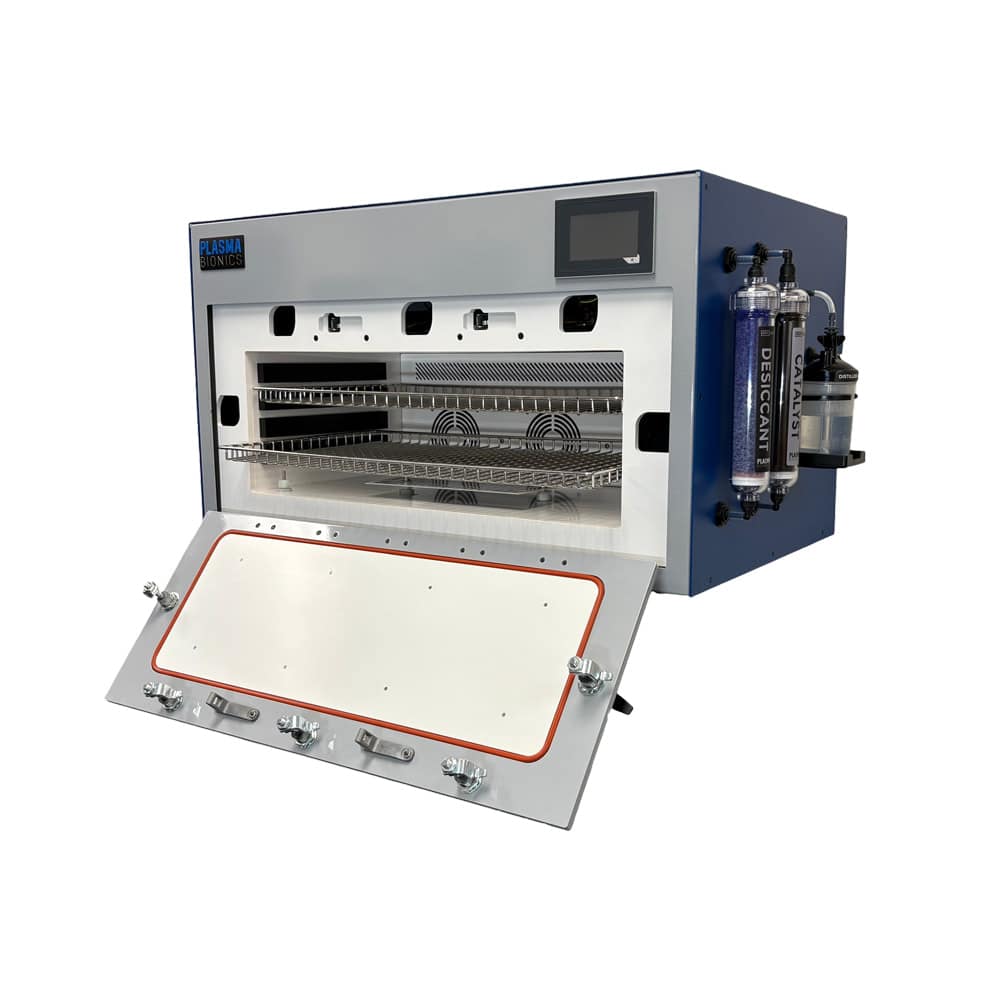

Advantages of the V20 Air Plasma Sterilizer:

- Low temperature: The Air Plasma Sterilization® process takes place at 40 °C (104 °F). This is well below the 60 °C (140 °F) required to be classified as a low temperature sterilization method. Heat-sensitive complex instruments composed of plastics and housing sensitive electronics or optics will not be damaged by Air Plasma Sterilization®.

- Low pressure: The Air Plasma Sterilization® process occurs at atmospheric pressure. It does not require high pressure like a steam autoclave or a deep vacuum like an ethylene oxide sterilizer.The minor pressure changes allow even the most delicate instruments to be sterilized without physical damage.

- Low cost per cycle: The cost per cycle for Air Plasma Sterilization® ranges between $3 and $5, depending on environmental conditions. This is less than a third the cost per cycle for ethylene oxide.

- Low maintenance: Maintenance of an Air Plasma sterilizer is minimal, consisting of simply wiping down the sterilization chamber with a damp cloth followed by a dry cloth every 15 sterilization cycles.

- Low power requirements: An Air Plasma sterilizer requires only a standard single-phase electrical outlet rated for 110-120 VAC and draws a maximum current of 6.5 amps. Two Air Plasma sterilizers can easily be run from a single power outlet. The total power draw is about one fourth that of a similarly sized steam autoclave.

- No installation cost: Unlike ethylene oxide sterilizers which often require modifications to a facility to exhaust the gases outside of the building, an Air Plasma sterilizer has no installation costs and can simply be plugged into a properly rated power outlet and is ready for use.

- No chemical consumables: The Air Plasma Sterilization® process uses just air and electricity. No chemicals are required.

- No Harmful byproducts: After a sterilization cycle is complete, the Air Plasma sterilant gases are passed through a catalyst that converts them back into air, producing no byproducts.

- Broad Material Compatibility: The Air Plasma sterilant gases are compatible with a wide variety of plastics, elastomers, and medical grade metals.

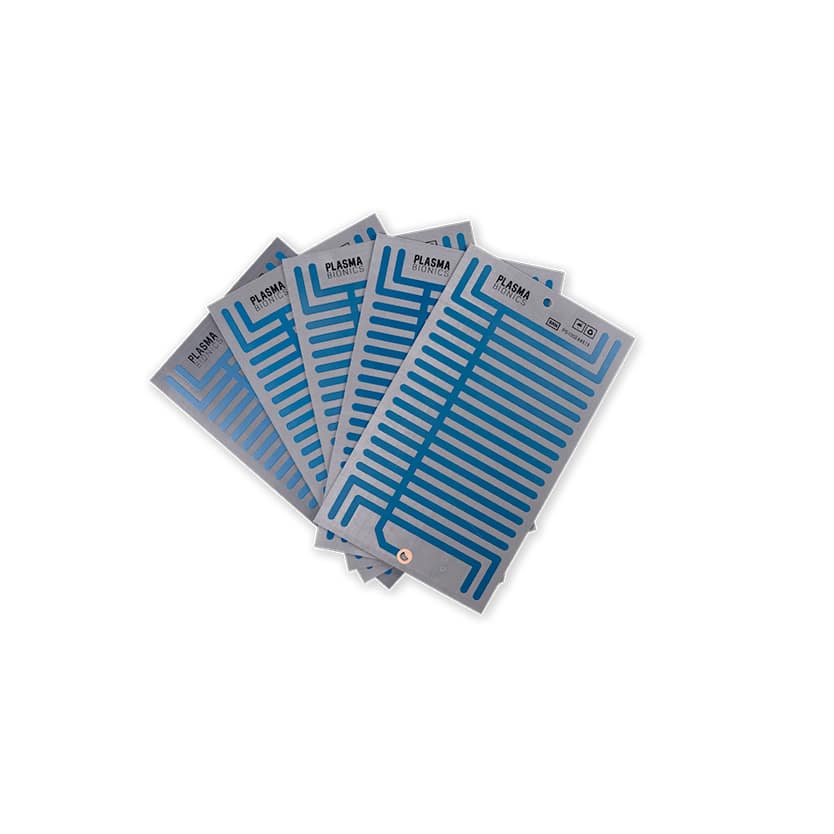

- Indefinite consumable shelf life: None of the Air Plasma Sterilization® consumables (plasma sheets, desiccant canister, and catalyst canister) have an expiration date.

Warranty

- 1 year (Extended warranty available*)

*Ideally, Extended warranty must be purchased before expiration of the standard warranty or extended warranty period. The customer can purchase extended warranty at time of purchase of the sterilizer and the extended warranty coverage will go into effect the day after the 1 year standard warranty expires.

Documents